Description

This complete water softener comes with Fine Mesh Resin 10 x 54 Black USA Mineral Tank loaded with 1.5 cubic foot of Fine Mesh Resin Black Brine Tank with Safety Float 1 inch (or ¾”) Noryl Plastic Bypass Fleck 5800 SXT Metered Control Valve.

With our comprehensive whole house water softening unit with high efficiency fleck 5800SXT metered control valve, you can get rid of the hard water that leads to scale buildup and decreased soap efficiency. In addition to removing iron from the water, fine mesh resin uses an ion exchange mechanism to eliminate the calcium and magnesium that generate hard water. Your pipes and appliances will last longer if you remove hard water! Meter-based regeneration: The regeneration technique used by this technology is meter-based. This implies that the system only regenerates when necessary and that the amount of water you consume is measured. The system regenerates more frequently to keep up as water needs rise. The most well-liked controller from Fleck, the 5600 sxt metered control, is based on the reliable 5800 valve. This system comes with a regular capacity brine tank that can carry roughly 250 lbs of salt. Installation requires simply 1-2 hours and a basic understanding of plumbing.

WHOLE HOUSE WATER SOFTENERS

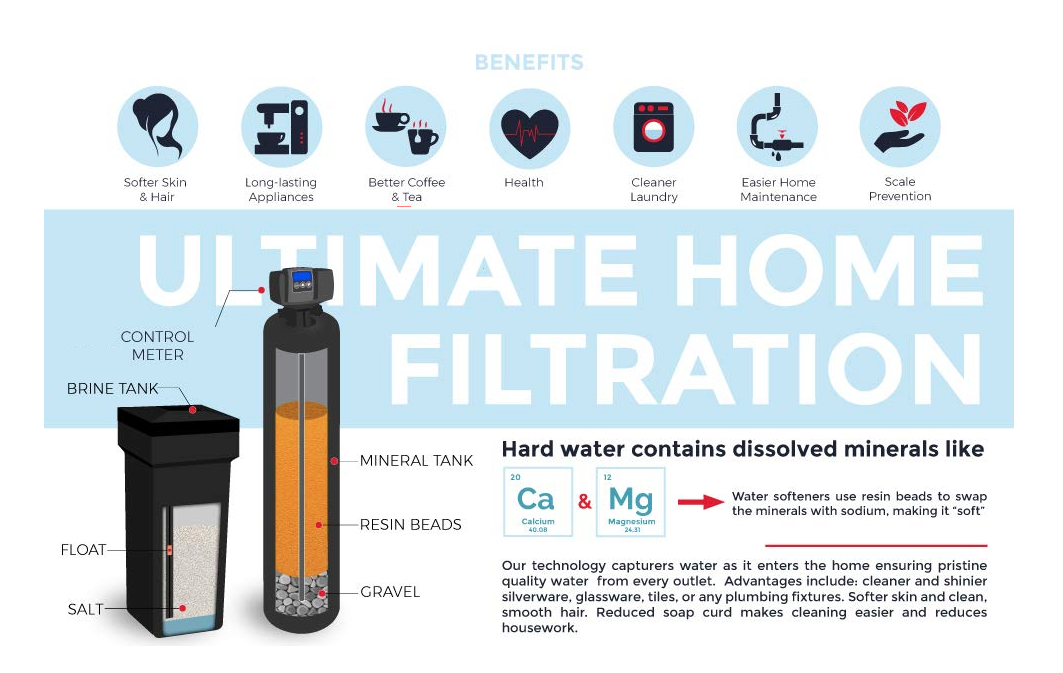

A conventional water softener is a mechanical device that is connected to the water supply system in your house. The basic idea behind all water softeners is the same: they exchange the minerals for another substance, usually sodium. We refer to this process as ion exchange.

A mineral tank is the main component of a water softener. It contains tiny polystyrene beads, sometimes referred to as zeolite or resin. There is a negative charge on the beads. Both magnesium and calcium in water are positively charged. This implies that when the hard water flows through the mineral tank, these minerals will stick to the beads. Though not as strongly as the charge on calcium and magnesium ions, sodium ions also contain positive charges. The sheer amount of the sodium ions in the classic water softeners is sufficient to push the calcium and magnesium ions off the beads when a very strong brine solution is pumped through a tank containing beads that are already saturated with these minerals.

When everything is operating normally, hard water enters the mineral tank, where it replaces sodium ions with calcium and magnesium ions. The water is exposed to the sodium ions. The device starts a 3-phase cycle of regeneration as soon as the beads are saturated with calcium and magnesium. To remove filth from the tank, the backwash phase first reverses the direction of water flow. The concentrated salt solution high in sodium is transported from the brine tank via the mineral tank during the recharge phase. Instead of the calcium and magnesium that are lost down the drain, the sodium builds up on the beads. After this stage is finished, surplus brine is removed from the mineral tank and the brine tank is filled again.

Sizing Your Softener:

The measurement of water hardness can be expressed as “milligrams per liter” (mg/l), “parts per million” (ppm), or “grains per gallon” (gpg). The majority of the industry uses gpg to determine softener size. To find your hardness value in grains per gallon, divide ppm and mg/l by 17.1.

It’s also necessary to take into consideration the iron and manganese content of your water. You can quickly calculate this figure by multiplying the concentration of iron and manganese (in ppm or mg/l) by 4. To the hardness value you calculated previously, add this amount. The overall value that results is more akin to a “compensated” hardness number and will help you size your softener more accurately.

We’ll assume 4 people living in the house, a hardness value of 10grains per gallon, and 2 ppm iron content in the example below.

Considering a household of 4 people, each using an estimated 75 gallons of water per day, and factoring in water hardness at 10 grains per gallon plus iron content at 2 parts per million (ppm) multiplied by 4, the total hardness to be addressed daily amounts to 5,400 grains. Therefore, for a system with a capacity of 32,000 grains, the effective operational capacity would be around 26,000 grains, accounting for a reserve capacity of 20%. With this setup, a metered unit would undergo regeneration approximately every 5 days, calculated by dividing the operational capacity (26,000 grains) by the daily hardness to be removed (5,400 grains), which is deemed acceptable

Use the formula above to adjust for the number of people actually living in your home, and your specific water hardness.

If your water has normal to low iron levels, you can design your softener to regenerate every 5 to 10 days. However, for higher iron (5 mg/l and higher) and manganese (1 mg/l and above) levels, it’s advisable to opt for more frequent regeneration to prevent buildup in the resin bed. In such instances, regenerating every three to five days might be necessary. If your water has exceptionally high iron levels, feel free to reach out to us via email or phone for personalized sizing recommendations.

METERED SOFTENING WATER SYSTEMS.

This system is good for 2-4 person home with high hardness.

This system includes:

- Fleck Valve

- Brine tank

- 1″ or 3/4″ BY PASS

- Distributor assembly

- Gravel for underbed- Pre-loaded

- Mineral Tank 10 X 54″- 1.5 Cubic ft of Upgraded 10% Cross Linked Cation Softening Resin- Pre-loaded for easy installation

Reviews

There are no reviews yet.